DESIGN AND ENGINEERING

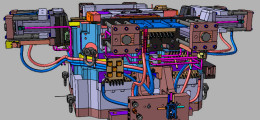

Our production activity has a wide range of different machines, always technologically advanced and in constant evolution, to guarantee the highest machining precision in the shortest amount of time possible. Continued investments in the purchase of 5 axis highspeed milling machines, new generation EDM, die holder milling, drilling, dimensional control machines for checking of impression parts allow us to increase our production capacity, to reduce the lead times, increasing continuously the quality standard of the product.

Our production activity has a wide range of different machines, always technologically advanced and in constant evolution, to guarantee the highest machining precision in the shortest amount of time possible. Continued investments in the purchase of 5 axis highspeed milling machines, new generation EDM, die holder milling, drilling, dimensional control machines for checking of impression parts allow us to increase our production capacity, to reduce the lead times, increasing continuously the quality standard of the product.

Our production activity has a wide range of different machines, always technologically advanced and in constant evolution, to guarantee the highest machining precision in the shortest amount of time possible. Continued investments in the purchase of 5 axis highspeed milling machines, new generation EDM, die holder milling, drilling, dimensional control machines for checking of impression parts allow us to increase our production capacity, to reduce the lead times, increasing continuously the quality standard of the product.